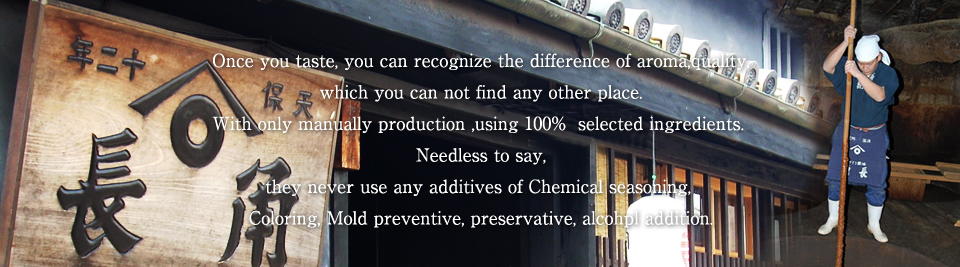

This is made at Yuasa,which is the birthplace of soy sauce.

It has been succeeded to a tradition of the brewing just as it used to be.

It made from natural soy beans , wheat and solt, which are all domestic ingredients.

After being carefully aged for over 1-3 years, it is slowly heated for half a day in cauldron over a wood fire of red pine. This is full-bodied,manually brewed.

■Storage,expiration date/ Store in a frige after opning a bottle.

It contains no preservations. Please use up within 2 years.

■Uses/It can be applied directly to "Tofu" or "Sashimi", especially fatty red fish such as tuna, amberjack, yellowtail.

It can be also used for "Teriyaki-steak", as flavouring meat.

In all kinds of cooking,including simmered dishes, you can find the excellece of aroma and taste.

They are inherited to produce raw soy sauce in a large vat made in a wooden, Yoshino ceder,warehouse built in 1841.

This aromatic, full bodied raw soy sauce is made from only the finest domestic ingredients and carefully aged over 2 years before the pure upper portion of the brew is skimmed and bottled.

■Storage,expiration date/ Store in a frige after

opning a bottle. It contains no preservations.

Please use up within 1 year.

■Uses/ It can be applied directly "Tofu" or "Sashimi",especially white fish such as sea bream or sole

and can also be brushed or dripping on steaks while grilling. Soaking meat into soy sauce for seasoning

makes meat much soft and rich. Especially, it is not until this soy sauce is used in boiling fish that you can recognize the

how rich aroma it is and shinining color it has.

In principle,The processing of raw materials, starting from the time of the cold months.

Until we delivery this soy sauce,it takes a year and a half through the fermentation and aging.

the taste, the aroma, and the color that soy sauce originally should have are created because of 2reasons.

1 Careful selection of raw materials

2 kobo-kin that inhabits in the storehouse in developing lovely soy sauce.